Novasep CDMO: an Axplora company

We are a full-service CDMO partner with a proven track record

For over thirty years, Novasep CDMO has partnered with leading pharmaceutical and biotech innovators to manufacture best-in-class APIs, partnering with our customers to improve the quality of life of millions of patients worldwide. We provide robust and sustainable contract development and manufacturing (CDMO) solutions for small molecule APIs and biopharmaceuticals. Our industrial footprint is made up of an extensive network of flexible cGMP manufacturing assets on multiple sites in full regulatory compliance, providing our customers with a secured supply chain.

Multi-site capacity with 10 API manufacturing sites in Europe and India

100% successful inspection rate by the US-FDA and European authorities

A reliable partner with decade-long relationships with key customers

Over 140 agile & responsive experts in process development

15 client drugs

approved by the FDA in the last 6 years

15 technologies

offered to customers

>90 M€

invested on our sites over the last 5 years

40 audits

per year

Explore our services and technologies:

API development

Explore our full range of services in the CDMO process development for your molecules.

API manufacturing

Discover our custom API manufacturing services offer from kilograms to tons.

HPAPI manufacturing

Find out more about our expertise in the development and cGMP manufacturing of HPAPIs.

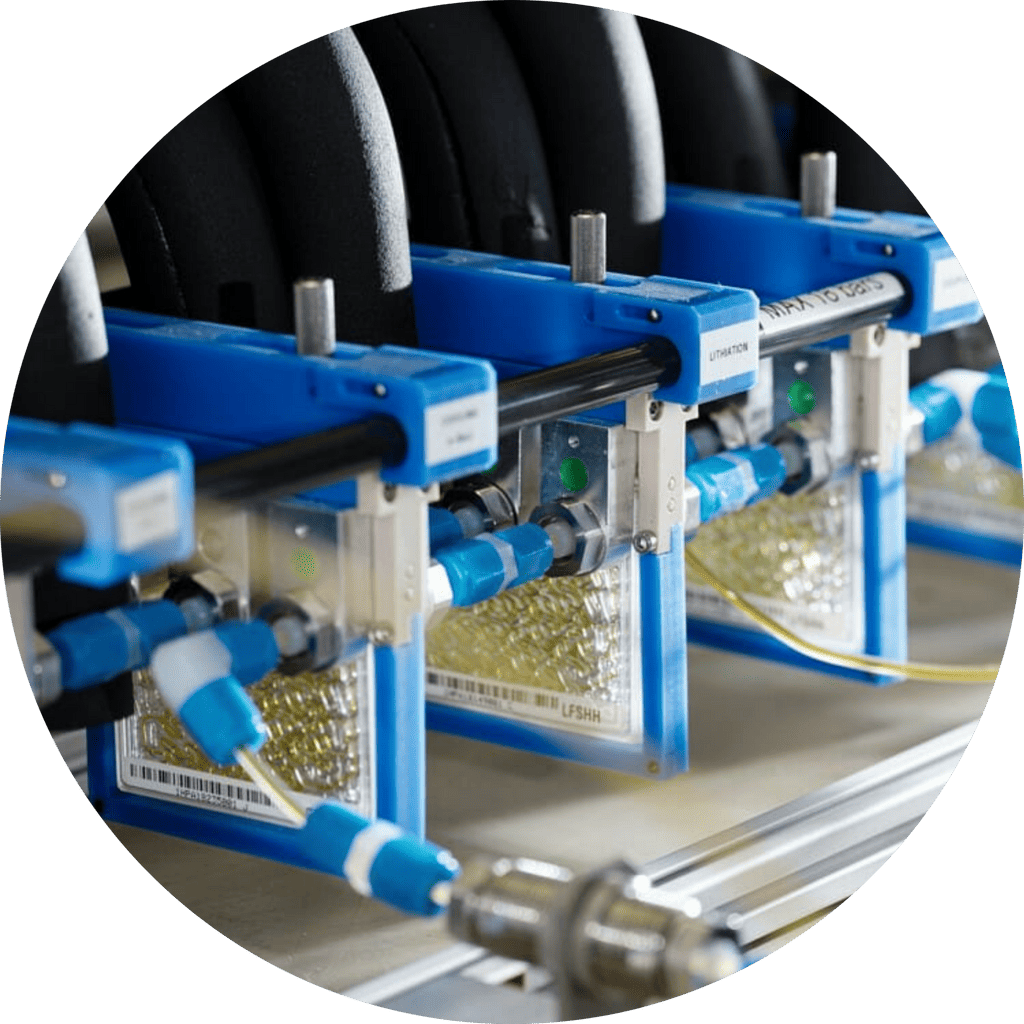

ADC manufacturing

Learn more about our unique services for the development and cGMP manufacture of ADCs, including the payload-linker and the bioconjugation.

ADC payloads manufacturing

Discover our solutions for ADC payloads, from development to cGMP manufacturing.

Hazardous chemistry

Discover our long track-record in developing and manufacturing APIs using high energy compounds at scale.

Electrochemistry

Learn how we can apply electrochemistry to support your development, scale-up and manufacturing needs for APIs.

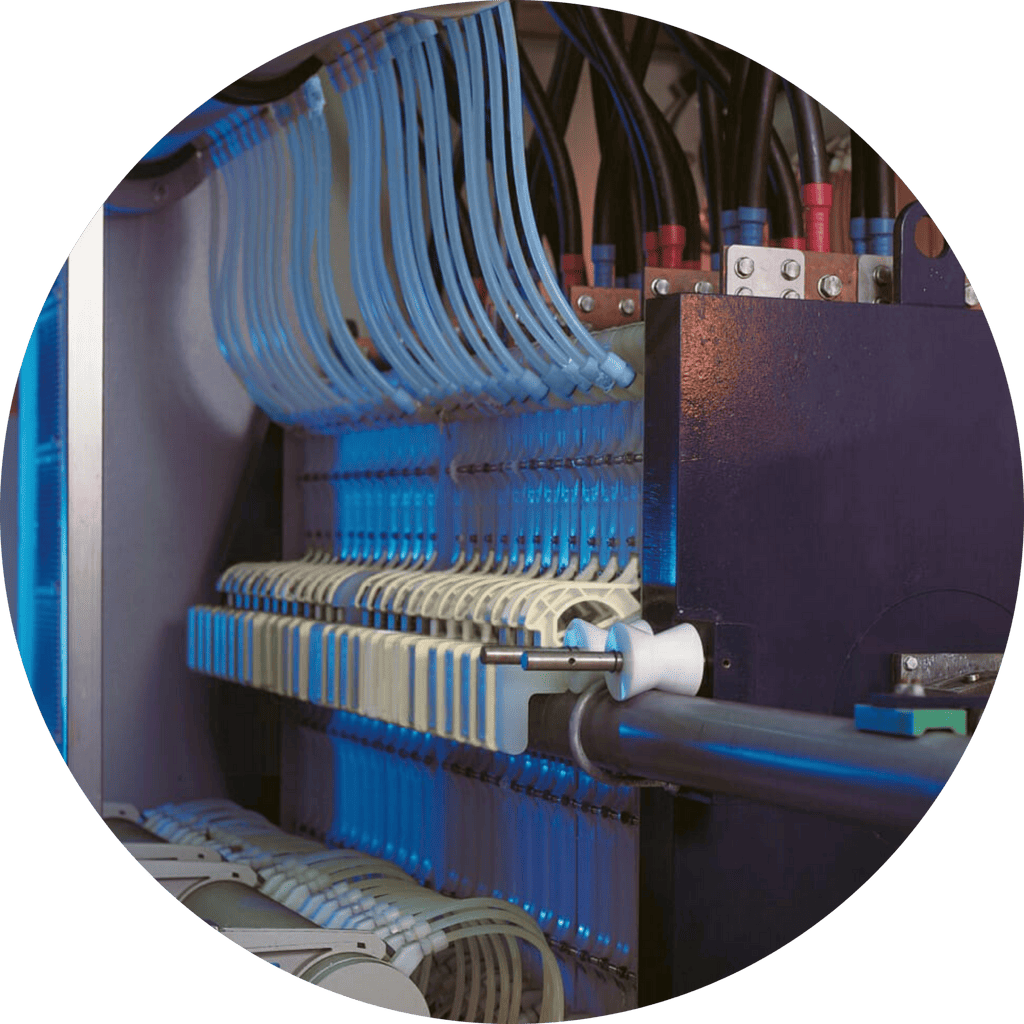

Small molecules purification

Discover what sets us apart as a world leader in small molecule purification.

Natural extracts and biomolecules purification

Find out more about our flexible range of development and manufacturing services to purify your natural extracts and biomolecules.

Flow chemistry

Explore our wide range of flow chemistry services, from lab-scale feasibility studies to validation.

Solid State chemistry

Explore our broad range of services in solid state chemistry and characterization of physical properties of APIs.

Lipid production

Explore our proven track record in lipid process development and manufacturing.