Beyond purification

Design & Build . Run & Perform . Upgrade & Revamp . Audit & Train

Let’s make together the best purification process to meet your needs

& get the most out of your production line.

Our offering

Let's collaborate on design and build the optimal purification process tailored to your requirements,

and ensure maximum efficiency for your production line.

Design & Build

Let’s design & build the best purification process to your needs, and boost your savings.

Run & Perform

Let’s get the most out of your production line, and boost your performance.

Upgrade & Revamp

Let’s make your historic process line a new state of the art one and boost your savings.

Audit & Advise

Let’s reach the optimum performance of your process & reduce your carbon footprint.

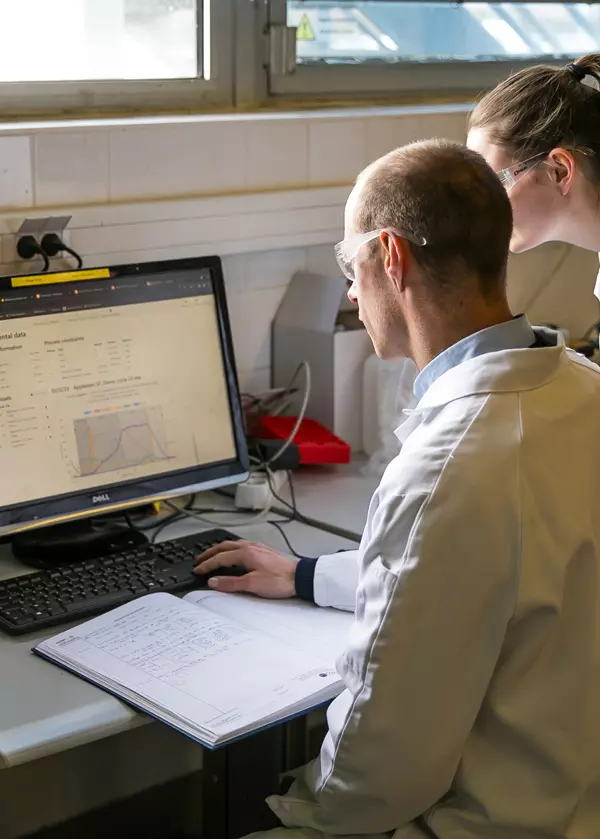

Assist & Train

Keep your teams at the edge of technical know-how & boost your performances.

We have issues getting data from the plants as this is largely a manual process; we expect help to interpret data and allow us to make the right decision. It should help us train our staff on how to make a judgment when facing a problem.

Specific impurities and variability of products cause challenge for the final product quality.

Our very first challenge is productivity. We must maximize the production of every asset.

Mess always happen during high production demand; we can’t choose the moment for maintenance.

Agility is key to maintain a flexible production line to meet rapidly changing customer needs.

Which technology for your separation

Explore the wide range of technologies we master to propose green and cost-effective solutions.

units designed, built and commissioned over the world.

+

0

applications studied and developped in our R&D centers.

+

0

customers regularly served all over the world.

+

0

years of experience in our purification technologies & consumables.

+

0

years in in-house characterization and algorithm development & modelization on our technologies & consumables.

+

0

Key markets

With years of presence in these markets, Applexion has developed design effective technologies, processes

and a unique application expertise to support you on your day to day production.

With years of presence in these markets, Applexion has developed design effective technologies, processes and a unique application expertise to support you on your day to day production.

Applexion

Our values

Innovation

We create new products, new services or ways of working.

Commitment

We challenge ourselves, we dare, and we stick to our word.

Care for people

We care for the ones we work with and for the ones we work for.